Most robot arms have six axes of motion, fewer than a human arm, but still plenty of range to automate complex industrial operations with speed, precision and consistency unattainable by humans. Although the cost of implementation has dropped dramatically over the years—from hundreds to tens of thousands of dollars—a robot is still a capital investment requiring a solid business case. Adding a 7th axis to a traditional 6-axis robot helps make that case by simplifying the transport of a single robot to multiple locations, functioning as robot transfer units (RTUs).

By design, the cobot segment within the robotics category provides collision protection to avoid human injury. When adding a 7th axis to extend robot arm capabilities, encompassing the collision protection for the 7th-axis controls strengthens the business case with a safer RTU design. With the collision protection included in the system, the RTU has now become a cobot transfer unit (CTU).

The benefits of a 7th axis

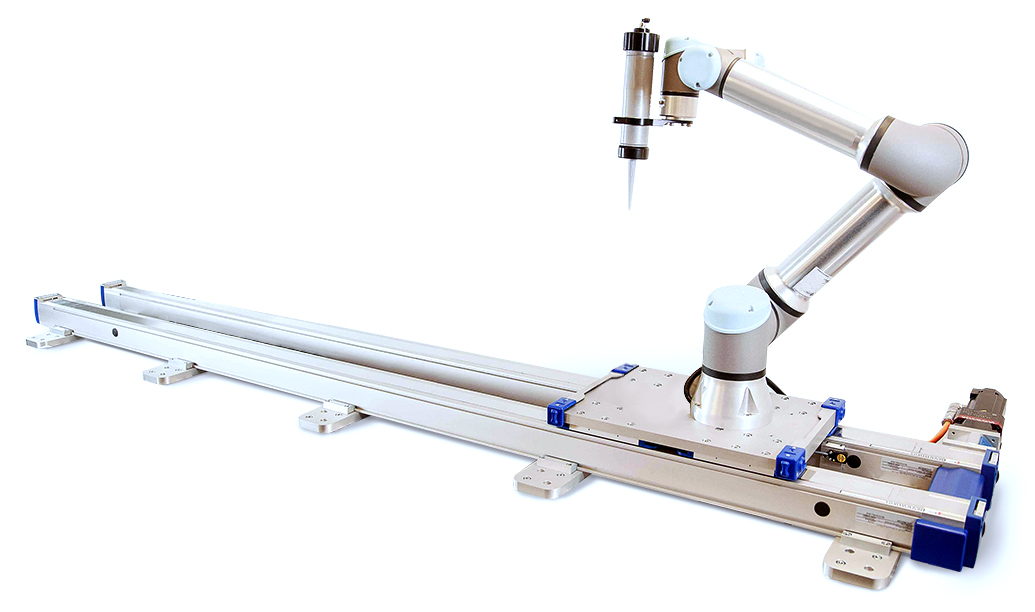

While 6-axis robots are usually fixed to a single location, a 7-axis system mounts the arm on a carriage attached to an actuation element. This moves the robot along an axis as long as 10 meters, dramatically extending the range of operation (Figure 1).

Figure 1. A robot transfer unit mounts a 6-axis arm on a carriage that enables transfer of the arm to multiple locations, allowing one robot to do the work of various robots. Image courtesy of Thomson Industries.

A movable robot opens many possibilities for cost efficiency, enabling the arm to extend its reach beyond the capabilities of a standard 6-axis robot. This extra degree of freedom makes it easier for the robot to navigate around obstacles, reach into tight spaces or serve larger work areas.

Adding a 7th axis combined with motion profile recipes for each part per workstation allows the user to program one robot to act like multiples. An assembly application might juxtapose four milling stations in a row. When the milling targets arrive, the arm selects one and serves it to the machine. Then, instead of idling in wait for the next part, the arm would move along the 7th axis to the next workstation, repeating the operation. Most robots can free drive, which simplifies the initial training. Some 7th-axis systems also have a free-drive mode, making the whole station training easy and flexible. A robot can work with larger part trays due to its extended reach capabilities. This enables it to do more in less time, perhaps working in an envelope holding a day’s worth of millwork while refreshing the base parts overnight.

When you review the initial cost of $50,000 to $100,000 per robot to serve each milling station, consider that one 7th-axis robot could move between comparable operations to accomplish all the work. ROI on a single robot could justify the purchase, delivering the traditional benefits with the highest efficiency. Factoring in the possibility of labor shortages further justifies the cost because a single robot solution could accomplish work that might be reprioritized. This reprioritization could be due to a lack of trained labor or low part demand, increasing the assigned labor cost in the first place.

The human touch

In the above milling example, plus a deployed cobot, it could be useful to have a human reviewing the full process. The program can be revised for optimization and checking the milled parts for quality. However, the need to tend multiple machines in such areas would make it difficult to address all the safety demands of operating machines and humans in such proximity per the risk assessment. Installing cages or other guard technology could greatly impact operational efficiency. A balance to meet the risk assessment and production requirements might allow the user to run the operation slower, but this could reduce throughput. Another approach would be to consider collision detection monitoring on the CTU as part of the overall risk assessment, combined with guarding or safety devices appropriate for the application.

Figure 2. Thomson's MovoTrak CTU uses collision detection paddles to sense unplanned loads from accidental human contact and stop motion. The robot arm is also sensitive to accidental human contact. Image courtesy of Thomson Industries.

CTU designers can afford such a capability by deploying collision detection paddles on both sides of the carriage, where an operator might instinctively put a hand (Figure 2). Forces as low as 13 N—about the force used in a computer keystroke—would be enough to signal the system to stop at once. A combination of current limit and position error monitoring would enable the detection, complementing similar sensing that may already be embedded into the joints of the robot arm. In all cases, users can adjust the sensitivity of both the 7th axis and the cobot arm. They should do this based on a risk assessment that considers the motion profile, moving materials and other application aspects.

Working together

In a CTU, the robots would handle the heavy lifting, precision welding and assembly tasks. At the same time, humans perform quality control, fine-tuning and complex decision-making processes, which can increase production speed and quality. Below are some applications that could benefit from human-robot collaboration:

Machine tending

In addition to the milling example mentioned above, machine-tending CTU applications include CNC, injection molding and presses, where one person can tend multiple machines with the same robot.

Material handling

Bin picking, packaging or palletizing could benefit by moving the robot arm to extend the human’s reach for heavy products in tight spaces.

Welding

Human control and monitoring of the arc of motion can enable longer welds.

Assembly

Human monitoring of insertion, nut driving, riveting and screw driving at multiple work locations can help maintain consistency.

Quality inspection, measurement and testing

Shared control of quality inspection devices, such as cameras and scanners, highlights and helps fix inefficiencies.

Dispensing

With automated dispensing of dense/sticky materials such as glue or sealants, humans could enable longer beads by monitoring for consistency and regulating accordingly.

Only the beginning

Whether you want to increase robot ROI in applications or design a new robot-based system, CTUs can provide quicker ROI and pay for themselves many times over.

First, they enable manufacturers to address those dirty, dull and dangerous applications (often called the “Three D’s”) more efficiently, with one cobot doing the work of many. Second, CTUs can fill gaps in staffing, enabling manufacturers to achieve production quotas that are otherwise impossible. Finally, they improve ROI by balancing human/robot collaboration. Humans provide planning, monitoring and decision-making capabilities, and the robots enforce efficiency in the Three D’s.

CTUs, however, are still young and becoming more affordable, easier to use and essential to a highly dynamic industrial market. They will likely be key enablers in what industry watchers call the “Fifth Industrial Revolution” or “Industry 5.0”. These terms describe human and robot technology combined with AI to bring previously unimagined levels of productivity and value. As engineers innovate to meet the demands of emerging markets, the greatest benefits of human/robot collaboration are yet to come.